Advanced Metal Stamping & Press Capabilities

Auckland-based production facility with 3-80 tonne gap-frame presses, tooling maintenance programs, and rigorous quality systems delivering repeatable components for roofing, HVAC, and lighting manufacturers.

3-80 Tonne

Gap-frame mechanical press range

±0.03 mm

Typical repeatable tolerance on qualified tooling

Rapid

Quote response for new enquiries

Safety Focus

Robust operator safety culture across every line

Core Manufacturing Expertise

Comprehensive support from tooling maintenance and partner-managed builds through to repeatable production and final inspection.

High-Volume Pressing

- Progressive, compound, and single-hit tooling

- Programmable feeds for steel, aluminium, and copper strip up to 200 mm wide

- Dedicated fixtures for roofing, HVAC, and lighting components

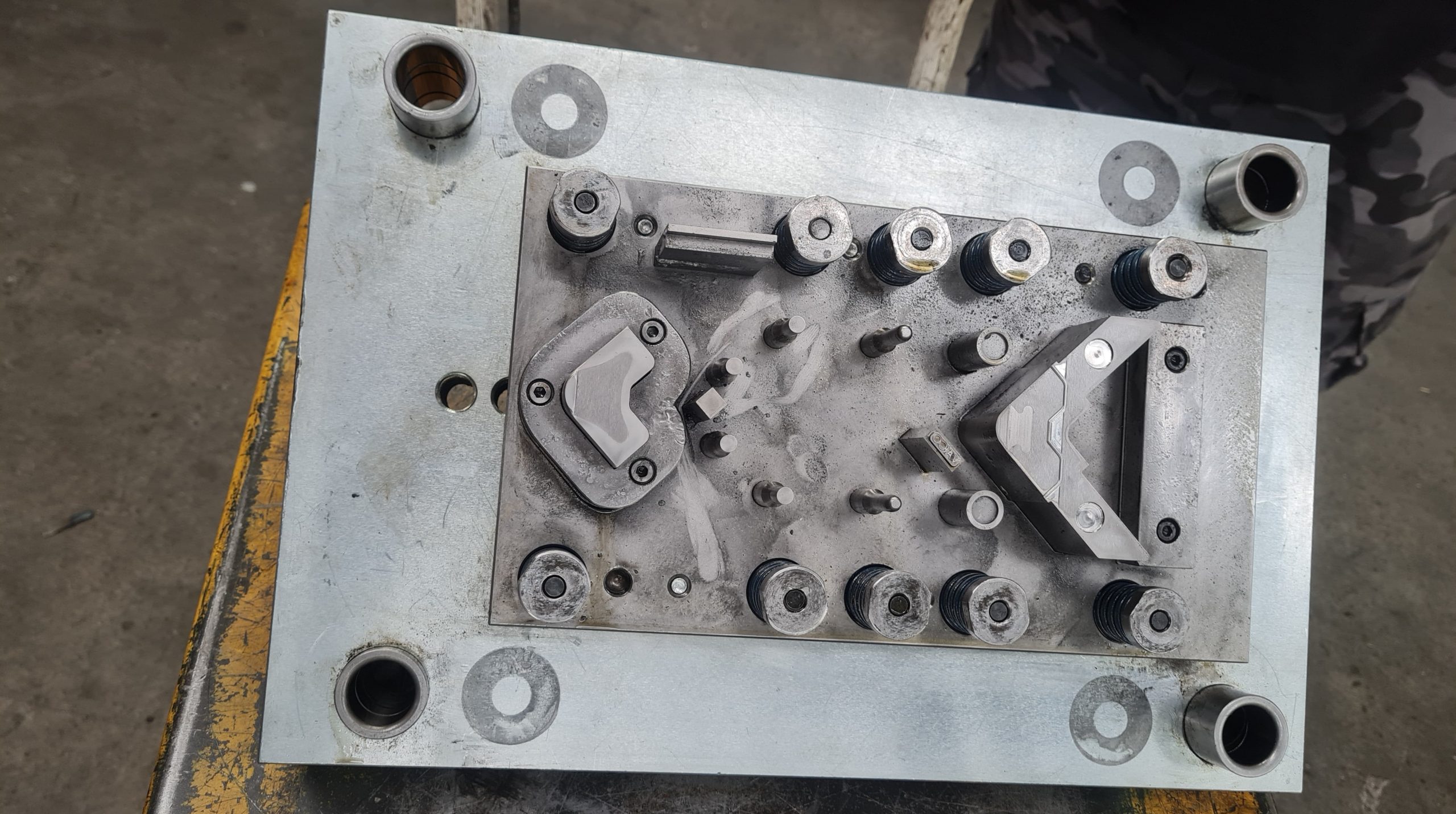

Tooling Maintenance & Partners

- On-site die maintenance programs and setup optimisation

- Trusted external toolmakers for new builds and complex refurbishments

- Preventative maintenance schedules to protect uptime

Quality & Traceability

- Structured in-process inspections and final checks

- Batch traceability for material origin and revisions

- Digital records aligned with ISO 9001 principles

Press & Support Equipment

Balanced press fleet supported by automation, coil handling, and safety systems for consistent results.

3-80 tonne gap-frame presses with configurable stroke and shut height.

Powered straighteners for sheet and strip up to 200 mm wide, enabling continuous production.

Robust safety systems and monitoring integrated across every production cell.

Our Production Process

Structured collaboration keeps projects on schedule from concept through to delivery.

Engineering Review

Assess drawings, tolerances, and material selection with your team. Recommend tooling approach for cost-effective runs.

Tooling Preparation

Coordinate tool design and manufacture with trusted partners, including try-outs and capability studies before release to production.

Press Production

Scheduled stamping with in-process checks, dimensional sampling, and packaging aligned to your requirements.

Quality Sign-Off

Final inspection report, traceable documentation, and logistics coordination for on-time dispatch.

Quality & Compliance

Proven systems safeguard accuracy, safety, and delivery performance.

Material Control

- Certified suppliers with heat/batch certification on request

- Segregated storage for stainless, galvanised, and aluminium stock

- Lot tracking back to coil identification

Inspection Systems

- Digital calipers, height gauges, and go/no-go jigs

- Critical dimensions recorded per inspection plan

- Corrective action workflow for non-conformances

Health & Safety

- Regular machine guarding audits and press certifications

- Operator training covering lockout, manual handling, and PPE

- SiteSafe-aligned procedures for contractors and visitors

Schedule a Manufacturing Consultation

Share volumes, materials, and delivery goals. Our team will confirm tooling options and provide a detailed quotation promptly.